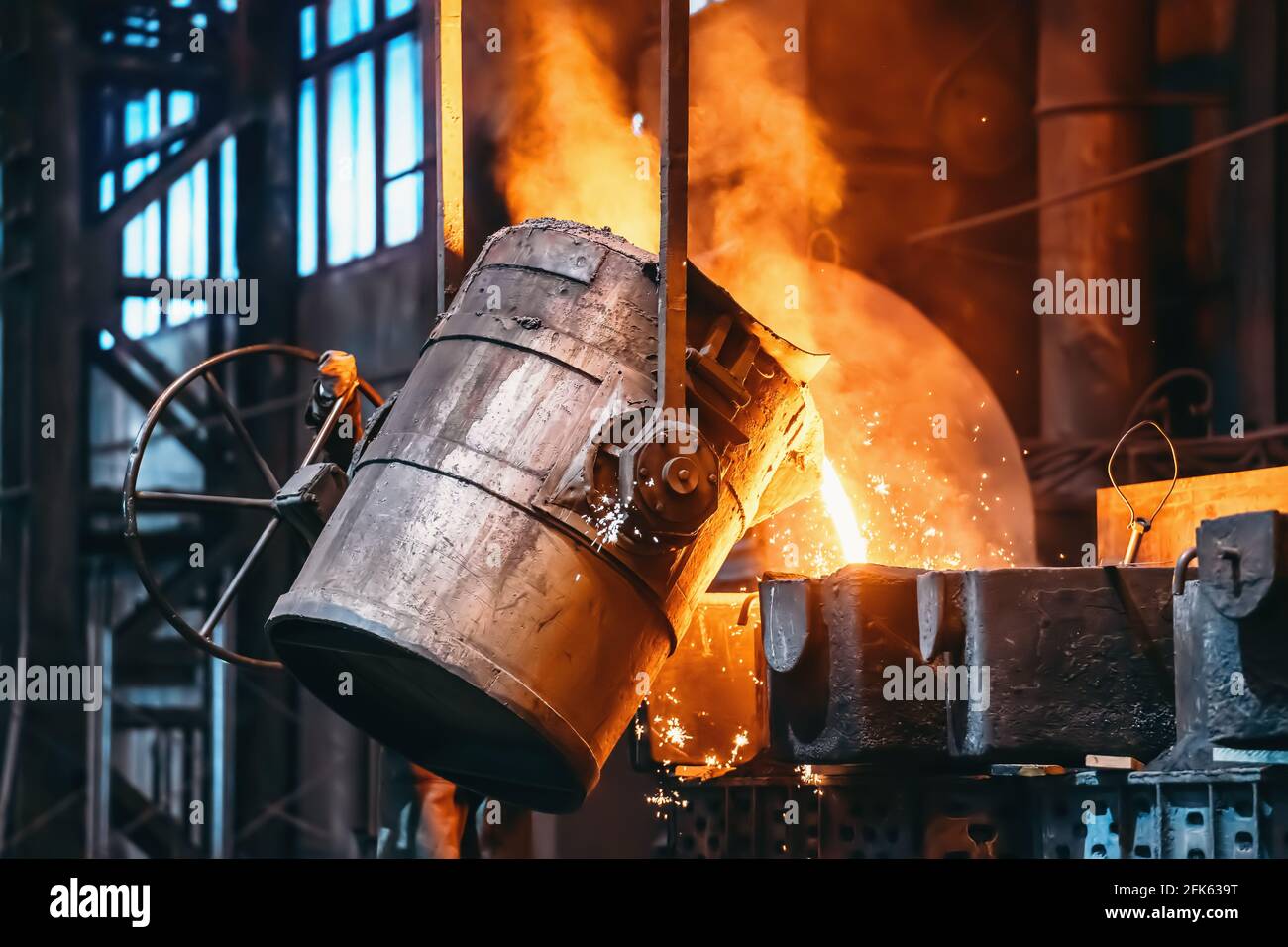

Metal Casting process outlined in a simple manner

Discover the Role of Metal Factories in Modern Manufacturing Processes

Steel foundries are important to the manufacturing landscape, transforming raw materials right into vital parts for various industries. Their advanced methods, consisting of 3D printing and CAD, make it possible for the creation of complicated get rid of minimal waste. On top of that, foundries are progressively taking on lasting techniques to enhance their environmental impact. Recognizing the full extent of these procedures discloses their significant influence on sectors such as auto and aerospace, prompting a closer examination of their progressing duty in modern-day production.

The Vital Functions of Metal Factories

Metal shops play an essential function in the production field by changing resources right into usable metal items with numerous procedures (Aluminum Foundry). These centers are necessary for creating components utilized in countless sectors, including automotive, aerospace, and construction. Shops largely concentrate on melting steel alloys and putting them into molds to create certain shapes, a process referred to as spreading

Shops offer customized solutions, such as warmth treatment, which boosts the mechanical residential or commercial properties of metal items. By assisting in these essential features, steel foundries add considerably to the overall effectiveness and innovation within the manufacturing landscape, making it possible for the production of a broad selection of steel goods.

Advanced Technologies in Metal Spreading

As the manufacturing sector evolves, progressed innovations in metal casting are improving the landscape of manufacturing. Advancements such as 3D printing and computer-aided design (CAD) have actually substantially improved the performance and accuracy of casting procedures. These innovations enable foundries to generate intricate geometries that were difficult or previously difficult to attain, therefore reducing product waste and improving general quality.

Furthermore, automation and robotics have structured operations, reducing hands-on labor while enhancing manufacturing rate. Incorporating advanced simulation software application enables shops to maximize casting layouts and forecast possible flaws before manufacturing, additionally boosting dependability.

Additionally, the introduction of smart manufacturing systems, including the Internet of Points (IoT), facilitates real-time surveillance of procedures, guaranteeing greater control over manufacturing criteria. These technological developments not only drive cost-effectiveness yet also position steel shops at the forefront of contemporary manufacturing, enabling them to fulfill the developing demands of numerous sectors.

Sustainability Practices in Foundries

While the manufacturing sector encounters enhancing stress to take on ecologically responsible techniques, factories are actively applying sustainability steps to reduce their environmental footprint. Several foundries have welcomed reusing efforts, utilizing scrap metal and various other materials to lessen waste and preserve resources. Advanced modern technologies, such as energy-efficient furnaces and automated processes, further improve their dedication to sustainability.

Foundries are likewise focusing on minimizing emissions and boosting air quality by embracing cleaner manufacturing techniques. The usage of ecologically pleasant binders and finishings has actually gained grip, lowering hazardous by-products in the casting procedure. Furthermore, water preservation steps are being carried out, with closed-loop systems minimizing freshwater consumption and wastewater discharge.

The Effect of Shops on Various Industries

Often ignored, shops play a crucial duty in supplying essential parts throughout a varied range of markets. These facilities are vital in creating steel castings made use of in automotive, machinery, aerospace, and construction sectors. In the auto sector, factories offer engine Full Article blocks, transmission situations, and other important parts, guaranteeing lorries operate successfully. Aerospace counts greatly on precision-cast components that meet rigid safety requirements, while construction companies depend upon strong and resilient steel products for infrastructure tasks.

Foundries add to the energy industry by producing parts for power generation devices, including generators and generators. Their flexibility extends to durable goods, where cast metal components enhance item capability and sturdiness. By sustaining different sectors, factories not just boost manufacturing abilities yet also drive technology and technical improvements, highlighting their substantial effect on the international economy.

Future Patterns in Steel Factory Procedures

Arising technologies and advancing market needs are shaping the future landscape of a fantastic read steel foundry procedures. Automation and robotics are significantly being integrated to enhance performance and reduce labor expenses. Smart factories are leveraging information analytics and the Net of Points (IoT) to monitor manufacturing processes in real-time, assisting in predictive maintenance and minimizing downtime.

Sustainability is also ending up being a focal point, with foundries embracing greener techniques by recycling materials and minimizing power usage. Advanced products, such as light-weight alloys and composites, are gaining traction, driven by industries such as aerospace and vehicle seeking enhanced efficiency.

Additive manufacturing is emerging as a complementary modern technology, enabling the manufacturing of intricate geometries that standard techniques can not achieve. As digitalization proceeds, steel shops are expected to embrace even more flexible production systems, enabling for tailored, on-demand manufacturing remedies. These fads show a transformative shift, positioning steel foundries for a vibrant future in manufacturing.

Frequently Asked Questions

What Products Are Typically Used in Metal Shops?

Steel factories typically make use of materials such as iron, light weight aluminum, bronze, brass, and various alloys. These products are selected for their distinct buildings, making it possible for the production of varied parts tailored for certain applications in countless industries.

Exactly How Do Foundries Ensure High Quality Control in Manufacturing?

Shops execute strict quality assurance actions, consisting of product evaluations, process monitoring, and screening of finished products. They use innovative modern technologies and standards to ensure reliability, consistency, and adherence to specs throughout the production process.

What Security Procedures Are Implemented in Metal Foundries?

Steel foundries carry out precaution such as individual protective tools, ventilation systems, routine safety and security training, and emergency methods. These practices aim to minimize threats connected with high temperatures, harmful fumes, and heavy machinery procedures.

The length of time Does the Steel Casting Refine Generally Take?

The metal casting process typically takes numerous hours to days, relying on aspects such as the intricacy of the style, kind of steel utilized, and cooling times needed for the details spreading technique utilized.

What Are the Profession Opportunities in Steel Foundries?

Job possibilities in metal factories consist of functions such as factory service technicians, metallurgists, quality assurance inspectors, device operators, and production supervisors - Aluminum Casting. These placements use diverse courses in manufacturing, design, and knowledgeable trades within the industry

Metal shops are indispensable to the manufacturing landscape, converting raw products right into necessary elements for various fields. Steel factories play a vital duty in the manufacturing sector by changing raw products right into useful metal items through click to read more different processes. In enhancement to casting, metal shops likewise involve in procedures such as machining, where excess material is removed to accomplish accurate specs. As digitalization progresses, steel factories are expected to embrace even more flexible manufacturing systems, permitting for personalized, on-demand production services. Job opportunities in metal factories consist of functions such as shop service technicians, metallurgists, top quality control examiners, equipment operators, and production supervisors.